Rom

Rom

- Home Appliances, Tools and Household Goods

- Consumer Goods & Electronics

- Products & Solutions for Enterprises

- Toți furnizorii

- Home Appliances, Tools and Household Goods

- Consumer Goods & Electronics

- Products & Solutions for Enterprises

- Toys & Goods for Kids

- Cookware

- Food storage containers

- Containers for spices and liquids_

- Drinkware

- Bottles for water

- Bakeware

- Посуда для сервировки стола

- Table setting accessories

- Vases_

- Knives_

- Cooking utensils

- Peelers, non-standard knives and manual hammers_

- Spoons, spatulas_

- Sieves and colanders_

- Kitchen scissors_

- Graters and manual food processors_

- Ladles_

- Cutlery

Hexagon Ragasco Composite gas cylinder HR24.5L, 24.5l, propane/butane 10kg/12kg, 30bar, Shell valve (Ukrainian standard), 5.4kg

Specificații tehnice Hexagon Ragasco Composite gas cylinder HR24.5L, 24.5l, propane/butane 10kg/12kg, 30bar, Shell valve (Ukrainian standard), 5.4kg:

Parametri esențiali

Lista completă a parametrilor

| Тип баллона | полимерно – композитный |

| Тип баллона по рабочему давлению | баллон низкого давления |

| Тип газа для заправки | LPG (СУГ) |

| Сфера применения | бытовое использование |

| Объем баллона | 24.5 l |

| Рабочее давление | 20 бар. (MAX: 30 бар.) |

| Резьба горловины | М 26x1,5 (6г/6Н) |

| Материал корпуса | композитный |

| We recommend to buy | |

Основные

| Тип баллона | полимерно – композитный |

| Тип баллона по рабочему давлению | баллон низкого давления |

| Тип газа для заправки | LPG (СУГ) |

| Сфера применения | бытовое использование |

| Рабочий температурный диапазон | от -40 ° C до + 50 ° C |

| Объем баллона | 24.5 l |

| Рабочее давление | 20 бар. (MAX: 30 бар.) |

Габаритные характеристики

| Высота баллона | 571 mm |

| Диаметр баллона | 305 mm |

| Вес пустого баллона | 5 kg |

Дополнительно

| Резьба горловины | М 26x1,5 (6г/6Н) |

| Резьба на выход к редуктору | М21,8/14 нитей, левая |

| Емкость (масса газа) | пропана - 10 кг / объем бутана - 12 кг |

| Уплотнение на горловине | не нужно |

| Материал корпуса | композитный |

| Температура окружающей среды при эксплуатации | от - 40 до + 60 °С |

| Температура окружающей среды при транспортировке | от - 50 до + 65 °С |

| Страна производитель | Норвегия |

| We recommend to buy | |

Ambalaj

| Lăţime | 300 mm |

| Înălţime | 580 mm |

| Lungime | 300 mm |

| Greutate | 5.35 kg |

| Volum | 0.0522 m3 |

Garanție

| Garanție | 24 luna |

Hexagon Ragasco composite gas cylinders have been developed as a modern alternative to traditional steel cylinders. They are designed for both household and industrial applications. The cylinder is made from modern polymer-composite materials and combines high safety in use, quality, excellent design, and innovation in the new gas industry.

nu este disponibil

Anunțați despre disponibilitate

Indicați email vostru şi vă vom anunţa imediat când produsul va fi disponibil

Anunțați despre disponibilitate

Vă mulțumim că ne-ați contactat.

La primirea bunurilor de vânzare, vă vom trimite scrisoarea la adresa e-mail indicată!

La primirea bunurilor de vânzare, vă vom trimite scrisoarea la adresa e-mail indicată!

Hexagon Ragasco Composite Cylinders – Explosion Proof, Convenient, Modern

Innovative Hexagon Ragasco composite cylinders are a high-quality solution for the safe use, storage and transportation of liquefied gases (propane, butane and their mixtures). The cylinders are manufactured in Norway from modern polymer-composite materials.

Cylinders Application Areas

- Domestic use (gas stoves, grills, ovens, gas and gasoline generators, heaters, camping, outdoor cooking, etc.)

- Industry (gas welding, plasma cutting, metal processing with a gas flame)

- Tourism (tourist gas burners)

- Energy (autonomous group gas cylinder installations)

Certification

Hexagon Ragasco cylinders are certified in Ukraine and the EU.

Main advantages of Hexagon Ragasco cylinders

- Increased explosion safety

- Modern design and innovations

- Light weight

- Rust-free

- Ultra-durable body (withstands a fall from a height of 2 m)

- Visibility of gas level in the cylinder

- Durability

- Carrying handle

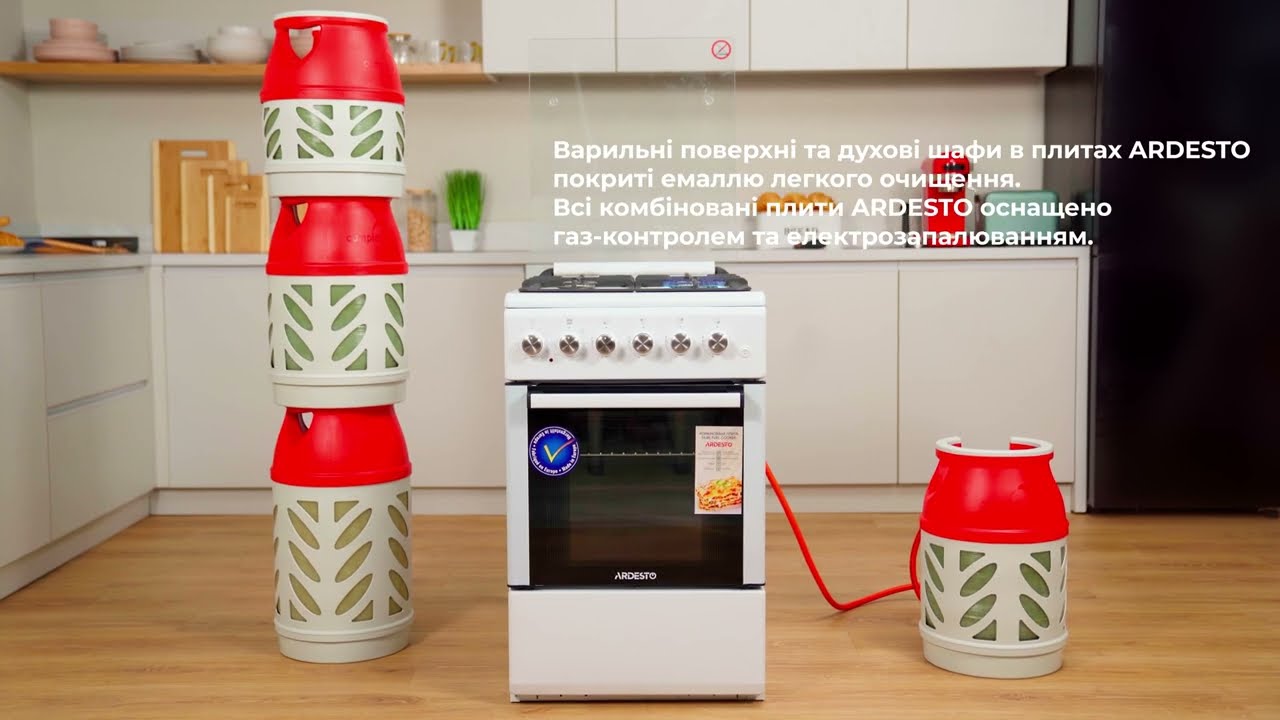

- Compact storage (possibility of placing the cylinder one on top of the other)

- The valve conforms to the Ukrainian standard (Shell type), has a left-hand thread for the reducer

- Made in Norway

What to Choose: Composite or Metal?

Despite the safety and numerous advantages of composite cylinders, there is still a demand for metal products. Why do people choose metal cylinders despite the high risk of explosion? The only argument is the lower cost. All the other arguments are in favor of composite cylinders, and the main one is safety, because the risk of explosion is eliminated, even when the product is on fire for a long time or in case of a direct hit from a shell or bullet.

Why Choose Hexagon Ragasco Composite Gas Cylinders?

Improved safety

Hexagon Ragasco composite cylinders have withstood many rigorous tests in various climatic conditions: -40°C arctic cold and +65°C desert heat. In addition, Hexagon Ragasco cylinders can withstand twice the bursting pressure of their metal counterparts, and they are also absolutely explosion proof. The risk of an explosion is completely eliminated even in the event of a fire, which has been proven by tests and experience in extremely difficult conditions.

Trials by fire

High-velocity shot impact test

Ergonomics

Composite cylinders are much lighter than their metal counterparts and are easier and faster to move: even when filled, they are lightweight, which is especially important when you often have to climb stairs to the upper floors. Ergonomic, modern, and structurally convenient for carrying and transporting thanks to the handles – openings in the body that both hide and protect the cylinder valve.

No rust

Composite cylinders do not rust. While this is an insurmountable drawback of metal products that require special operating conditions because of this.

Transparency

You can control the level of gas filling in the cylinder through the transparent matte wall of the product. The translucent body of the Hexagon Ragasco eliminates the need for additional measuring devices. The user can easily check the amount of gas remaining and determine when a refill is needed.

Durability

The service life is 20 years from the date of manufacture. With proper use, storage, and periodic inspection (at least once every 10 years), composite cylinders will last even longer.

Manufactured in Norway

Hexagon Ragasco composite gas cylinders are manufactured in Norway. The fully automated plant in Raufoss uses state-of-the-art technology and strict quality control standards to ensure that Hexagon Ragasco cylinders meet the highest safety and reliability requirements.

Design Features

Safety gas cylinders are made of a composite material consisting of fiberglass coated with epoxy resin. The fiberglass layer provides strength and impact resistance, and the epoxy resin provides resistance to corrosion and chemicals. For ease of use, the cylinder is enclosed in a polymer casing. The valve and gas reducer are protected from any damage. The cylinder valve has no fluoroplastic sealing materials or sealants, and the built-in O-ring and tapered metal-to-metal connection ensure a leak-free seal for the entire service life.

CAUTION!

For the correct functioning of the cylinder and gas equipment, read the rules for filling gas cylinders!

Hexagon Ragasco Gas Cylinders Filling Rules

First Filling

- 1. Before the first filling, unscrew the valve and release the compressed air.

- For proper filling and further normal operation of any devices operating on liquefied propane, butane or propane-butane mixture, the cylinder must be filled with gas to no more than 80% of its total volume!

It is important to leave room for an «air cushion» in the cylinder, which is the free space required to convert liquefied propane-butane into gas.

Refilling (calculation by weight)

- During each filling, the volume of gas remaining in the cylinder must be checked on on scales.

- After that, subtract the known unchanged weight* of the empty cylinder (*the weight of the cylinder with the valve, which is indicated in the product description) from the result just obtained (the weight of the cylinder with the valve). The calculated difference is the weight of the remaining gas in the cylinder. It should be noted that the average density of a propane-butane gas mixture is approximately 0.54 kg g per 1 l.

- The rest of the gas can be refilled without exceeding the limit values and guided by the weight data from the table below, according to the gas used – propane, butane or a mixture of both.

Gas Volume and Weight Recommended by the Manufacturer for Filling Hexagon Ragasco Cylinders

Gas Cylinders

| Code | 100578 | 100579 | 100580 | 100581 |

| Empty | 3.4 | 4.1 | 5 | 7.5 |

| Empty with a valve | 3.9 | 4.5 | 5.4 | 7.9 |

| Propane, kg | 5 | 7.5 | 10 | 14 |

| Butane, kg | 6 | 8.5 | 12 | 16.5 |

| Volume, l | 12.5 | 18.2 | 24.5 | 33.5 |

| Operating volume, l | 10 | 14.5 | 19.5 | 26.5 |

| Weight of the full with propane-butane, kg* | 9.3 | 12.3 | 15.9 | 22.2 |

*Information is averaged, depending on the propane-butane mixture

Hexagon Ragasco composite LPG cylinder valves

Shell valves (1) in all gas cylinders have a left-hand thread (3) and are opened by turning the valve

wheel (2) to the left. There are cases when the rotary wheel of the valve (2) is twisted too tightly on

the cylinder, so sometimes more effort is needed to open it. In this way, the manufacturer fixed the

rotary wheel of the valve (2) during production (there are cases when the valve is in the "Open"

position).